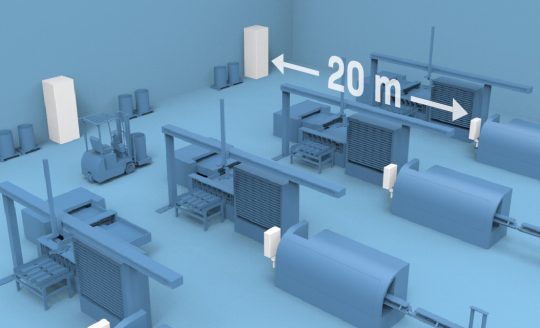

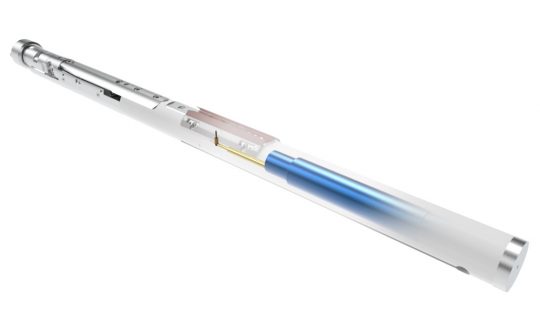

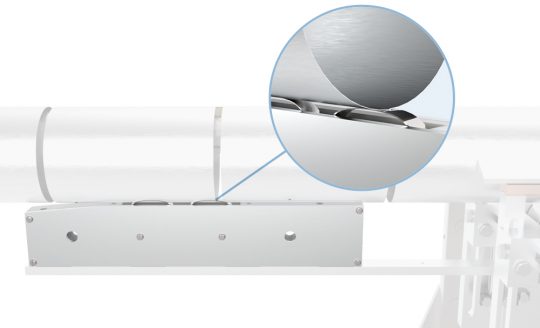

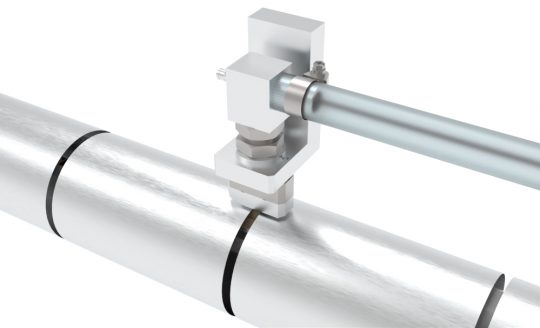

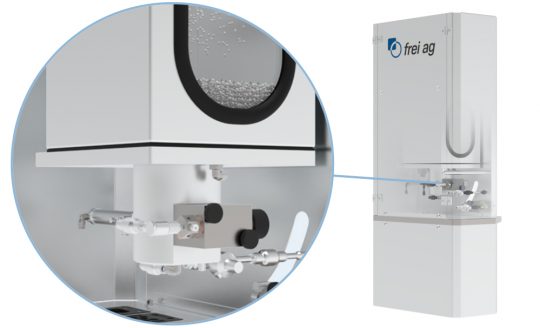

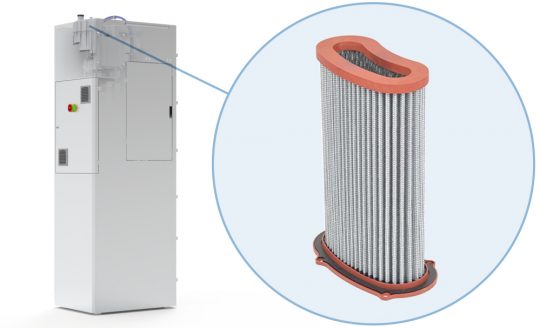

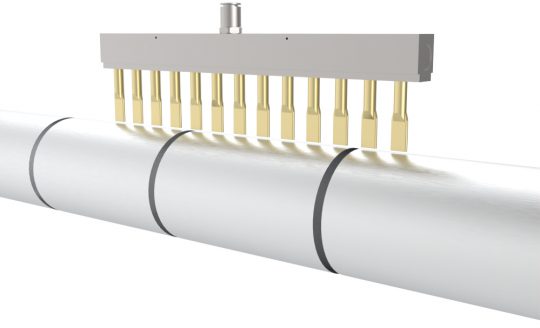

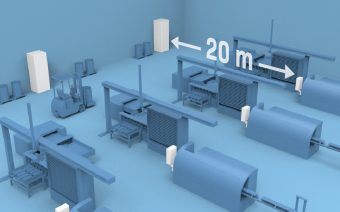

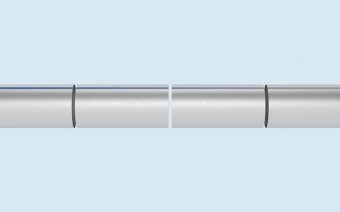

Powder coating system for internal seam protection. Universally applicable for all types of welders.

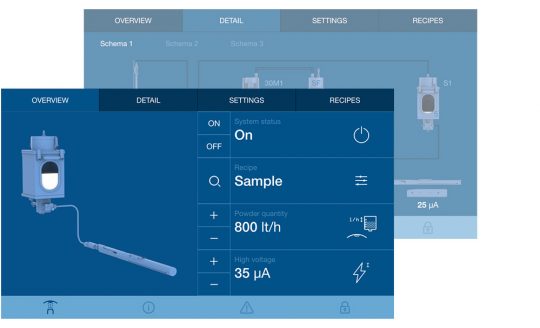

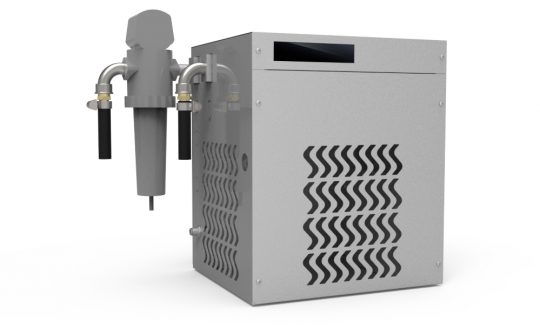

State of the art technology, equipped with high performance components. Safety features and interactive error messages in touch screen. Designed for processing BPAfree and BPAni powder types.

Made in Switzerland.