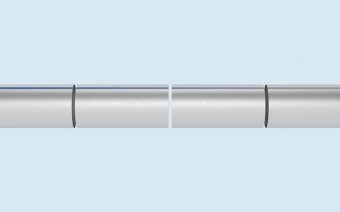

Seam Curing

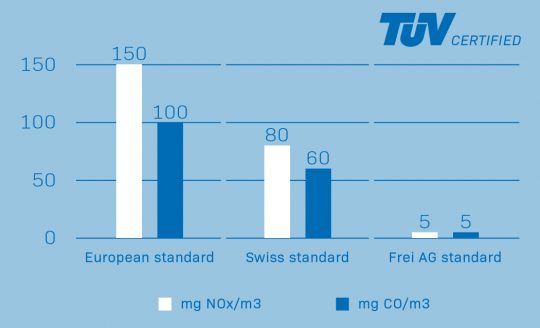

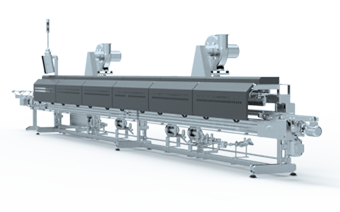

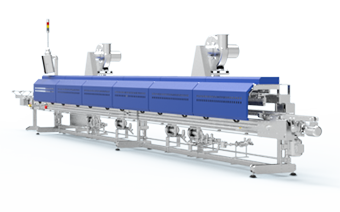

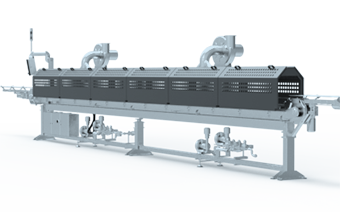

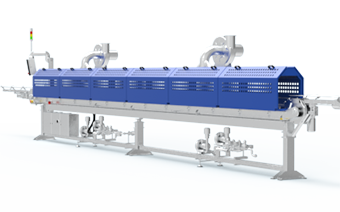

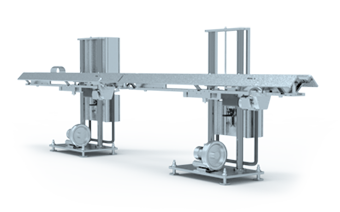

State-of-the-art gas curing systems with lowest NOx and CO concentrations guarantee that the Frei curers comply with any Clean Air Legislation. The technology permits highly efficient curing and polymerization of powder and wet lacquers with cost-effective utilization of energy.

Available product(s)

- Can sizes

- Production capacity

- Active heating lengths

- Construction

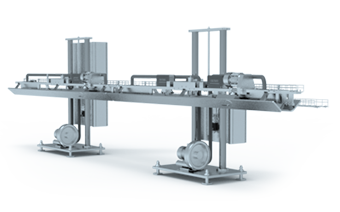

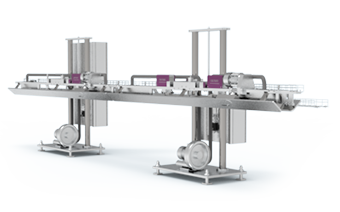

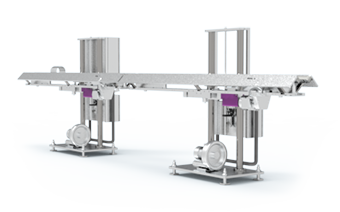

Induction curer modularly constructed for all side seam protections (powders and wet lacquers). Induction heating is characterized by highest energy efficiency.

Available product(s)

- Can sizes

- Production capacity

- Active heating lengths

- Construction

State-of-the-art gas curing systems with lowest NOx and CO concentrations guarantee that the Frei curers comply with any Clean Air Legislation. The technology permits highly efficient curing and polymerization of powder and wet lacquers with cost-effective utilization of energy.

Available product(s)

- Can sizes

- Production capacity

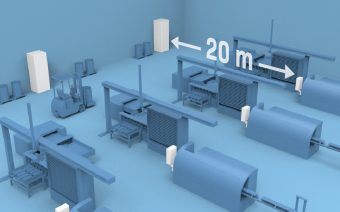

- Active heating lengths

- Construction

Induction curer modularly constructed for all side seam protections (powders and wet lacquers). Induction heating is characterized by highest energy efficiency.

Available product(s)

- Can sizes

- Production capacity

- Active heating lengths

- Construction

Products

Need pre-sales support or an offer?

We are happy to assist you!

Please send your request to sales.frei-ag@soudronic.com